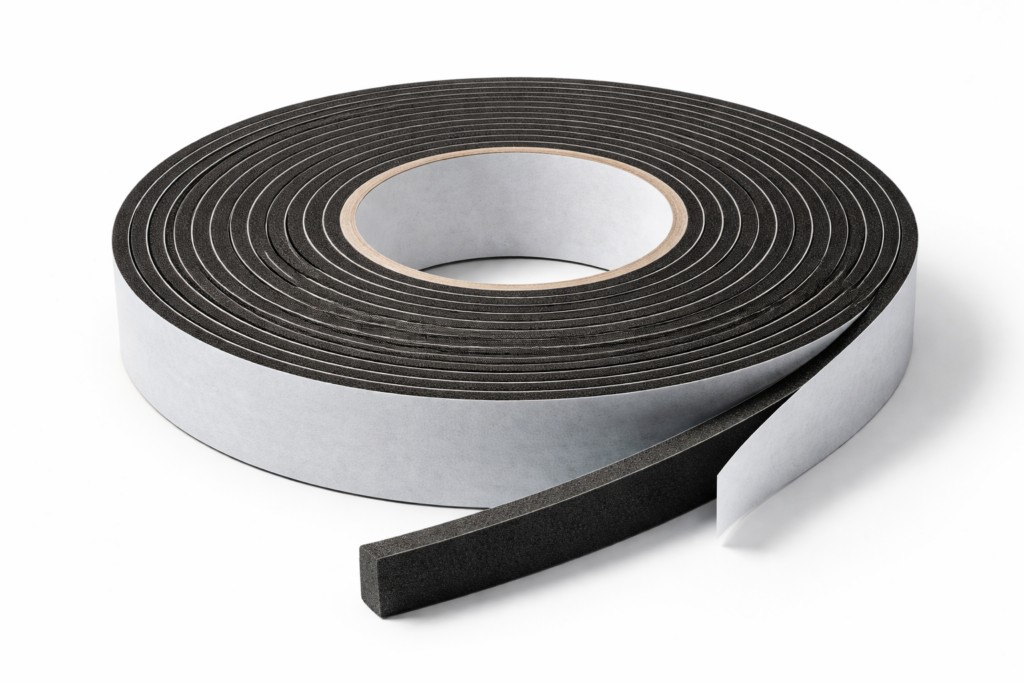

Foam tape is used across industries like construction, automotive, and HVAS to seal, cushion, and insulate different aspects of projects. Trusted for its reliability and durability, foam tape is a standard. However, without proper installation, foam tape can quickly fail. Understanding common foam tape installation errors and how to avoid them can significantly improve performance, extend service life, and reduce costly rework or maintenance.

Mistake One: Poor Surface Preparation

One of the most frequent causes of foam tape failure is inadequate surface preparation. Adhesive-backed foam tapes rely on seamless contact between the adhesive and the substrate. Anything like dust, oil, moisture, or rust can prevent proper adhesion from the get-go.

Before applying foam tape, the substrate should be clean, dry, and free of contaminants. In many cases, wiping the surface with a compatible solvent and allowing it to fully dry is sufficient. For metal surfaces, removing oxidation or corrosion may also be necessary. Skipping this step often leads to early adhesive failure, especially in demanding environments.

Mistake Two: Installing at the Wrong Temperature

Temperature and climate play a critical role in adhesive performance during installation. While many foam tapes are designed to perform across wide temperature ranges once installed, most pressure-sensitive adhesives require a minimum application temperature to achieve proper wet-out.

Installing foam tape in conditions that are too cold can prevent the adhesive from flowing into the microscopic surface irregularities needed for a strong bond. As a result, the tape may appear secure initially but fail under load or environmental stress. Whenever possible, installation should occur within the recommended temperature range, typically 40 °F to 60 °F. In colder environments, pre-warming the tape and substrates can help ensure proper adhesion.

Mistake Three: Stretching the Tape During Application

Stretching foam tape during installation is a subtle but common mistake. When tape is pulled tight as it is applied, internal stress is introduced into the foam and adhesive. This tension will cause the tape to try to shrink back to its original length, leading to edge lifting, gaps, and seal failure.

To avoid this issue, foam tape should be laid down gently without tension. Allow the tape to rest naturally against the surface, following contours without being forced. This approach helps maintain consistent compression and long-term seal integrity.

Mistake Four: Inconsistent or Insufficient Pressure

Pressure-sensitive adhesives require firm, uniform pressure during installation to fully activate the bond. Simply placing the tape on a surface with too little compression can leave portions of the adhesive under-engaged, reducing bond strength.

Applying consistent pressure along the entire length of the tape ensures proper contact and adhesive wet-out. This can be done by hand for small applications or with rollers or presses in production environments. Uneven pressure often results in weak spots that become failure points under vibration, temperature changes, or moisture exposure.

Mistake Five: Over-Compression of the Foam

Though compression is necessary to adhere tape, too much pressure can be just as problematic as too little. Over-compressing foam tape can collapse the cell structure, leaving it ineffective for cushioning and sealing. This is especially critical in applications where the foam must absorb movement, vibration, or thermal expansion.

Proper joint design accounts for the foam’s recommended compression range. Selecting the correct thickness and density helps ensure the tape provides sealing and cushioning without being crushed beyond its functional limits.

Mistake Six: Using the Wrong Foam or Adhesive for the Application

Not all foam tapes and adhesives are designed for the same conditions. Using a product unsuited to the environment can lead to rapid degradation or failure. For example, a foam tape with poor UV resistance may perform well indoors but fail quickly outdoors. Similarly, a tape with high initial tack may not provide the long-term durability needed in high-temperature or high-moisture settings.

Choosing the right foam tape involves considering substrate compatibility, temperature exposure, moisture levels, chemical contact, and mechanical stress. Consulting product data or working with an experienced supplier helps ensure the selected material aligns with application requirements.

Mistake Seven: Ignoring Environmental Exposure After Installation

Installation conditions are only part of the equation. Long-term environmental exposure also affects foam tape performance. Exposure to water, chemicals, UV radiation, and temperature cycling can all impact adhesion and foam integrity.

Designers and installers should consider how the tape will be protected after installation and the intended use case. In some cases, additional mechanical retention, edge sealing, or shielding from direct exposure may be necessary to ensure long-term durability.

Mistake Eight: Skipping Testing or Validation

Relying solely on assumptions rather than testing can lead to costly failures. Conditions in real-world applications often differ from ideal lab environments. Without validation, even well-intentioned installations may fall short of performance expectations.

Testing foam tape in actual or simulated operating conditions helps identify potential issues before full-scale deployment. Evaluating adhesion, compression recovery, and environmental resistance under realistic conditions provides confidence that the solution will perform as intended.

Gaska’s Approach to Reliable Foam Tape Performance

At Gaska Tape, we understand that material performance and installation practices go hand in hand. Our team works closely with manufacturers and installers to recommend foam tapes engineered for specific environments and performance requirements. We provide guidance on installation best practices, conduct lab testing to validate performance, and offer rapid prototyping to evaluate materials before full production.

By combining engineered foam solutions with practical application expertise, we help reduce installation errors and deliver consistent, long-term performance.

Foam tape failures are often preventable. By understanding common installation mistakes and taking steps to avoid them, you can improve seal reliability, reduce maintenance, and extend product life. Contact Gaska Tape to discuss your application, review installation requirements, or find a foam tape solution that performs from day one.