In industries like automotive manufacturing and industrial machinery, vibration is an unavoidable challenge. Though some vibration is always expected, excessive or uncontrollable vibration can wear equipment out prematurely. With the right foam materials, vibration can be absorbed, isolated, and controlled, extending the lifespan of certain machinery.

The Problem with Uncontrolled Vibration

Vibration occurs when mechanical energy causes components to move back and forth, typically in a cyclical pattern. While machinery and equipment are designed to operate with some degree of vibration, excessive or sustained vibration can cause a range of issues, including:

- Mechanical Fatigue: Repeated stress cycles can weaken metals, plastics, and adhesives.

- Fastener Loosening: Bolts, screws, and other mechanical connections can work themselves loose over time.

- Seal and Gasket Failure: Vibration can cause seal wear, compression loss, or complete detachment.

- Noise Generation: Vibration often translates into unwanted sound, reducing user comfort or violating noise-level regulations.

- Precision Loss: Sensitive instruments and equipment may produce inaccurate results when exposed to vibration.

The cumulative effect is reduced operational reliability, increased maintenance costs, and, in some cases, unsafe operating conditions.

How Foam Materials Control Vibration

Foam materials help manage vibration through three primary mechanisms. First, foam converts kinetic vibration energy into low-level heat through internal friction, dissipating it before it transfers to other components. Foam also serves to separate vibrating components from the surrounding structures, preventing the spread of vibration. Finally, foam reduces the amplitude (intensity) of vibration cycles, making them less damaging over time.

The effectiveness of foam in vibration control depends on several factors, including its density, cell structure, thickness, and integration into the assembly.

Key Foam Properties for Vibration Control

When specifying foam for vibration control, engineers must evaluate several performance characteristics. Density is a key characteristic in preventing vibration spread. Higher-density foams generally provide greater load support and resistance to compression, which can improve vibration isolation in heavy-duty applications.

Additionally, compression set resistance, or the foam’s ability to recover its original shape after being compressed, ensures long-term effectiveness against vibration damage. Dynamic stiffness can also impact a foam’s resistance to vibration. This characteristic represents the balance between rigidity and flexibility, determining how the foam responds to vibrations. These properties must be matched to the vibration profile of the application, which includes frequency, amplitude, and load conditions.

Common Applications

Foam materials for vibration control are found in a wide range of industries and equipment designs:

- Automotive: Engine bay seals, dashboard insulation, and door panels use foam to reduce road noise and vibration, improving passenger comfort and component durability.

- Industrial Machinery: Foam pads, gaskets, and isolators help protect sensitive electronics, reduce operator fatigue, and prevent fastener loosening.

- HVAC Systems: Foam strips and gaskets dampen compressor vibration and fan noise while sealing air paths.

- Electronics: Precision instruments and devices use foam to protect delicate circuits and sensors from vibration damage.

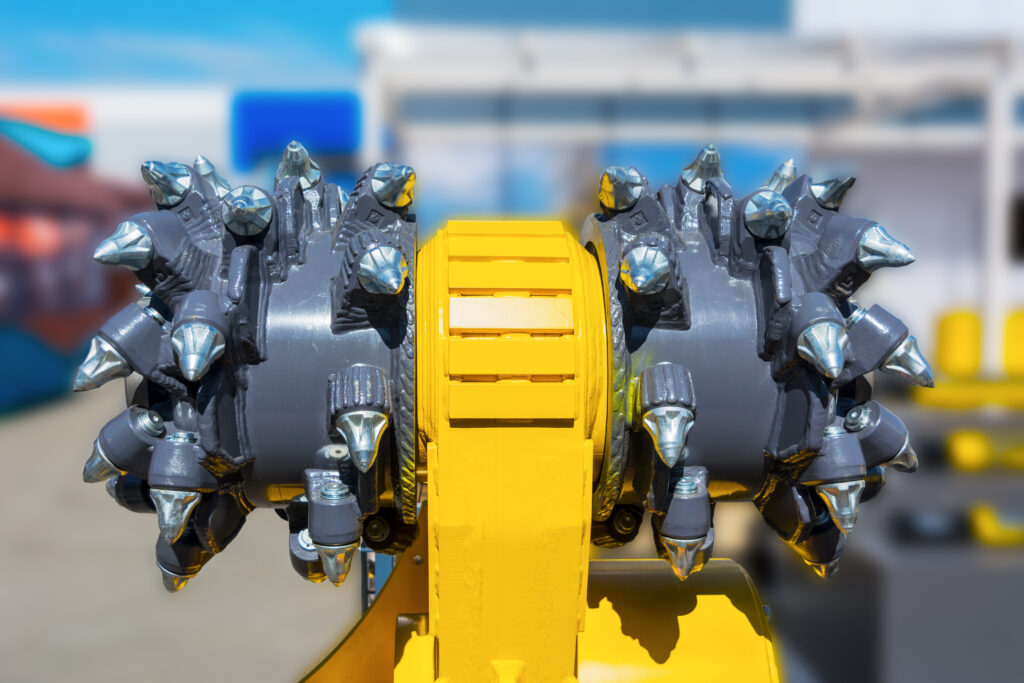

- Construction Equipment: Foam isolation mounts protect hydraulic systems, operator cabs, and glass panels from excessive vibration during heavy use.

Each usage of foam presents unique challenges concerning vibration control, requiring careful selection of foam type, thickness, and configuration.

Design Considerations for Effective Vibration Control

Incorporating foam into a design for vibration control requires a comprehensive understanding of the system as a whole. Key considerations include:

- Vibration Frequency and Amplitude: Different foam formulations perform better at specific frequency ranges. Matching foam properties to the vibration profile ensures optimal damping.

- Load Distribution: The foam must support the static load of the component while still allowing for vibration isolation.

- Compression and Thickness: Thicker foam can absorb more energy, but over-compression can reduce effectiveness.

- Mounting Method: Adhesive-backed foam can be applied directly, while other applications may require mechanical fastening or encapsulation.

- Environmental Exposure: Temperature, moisture, and chemical exposure should be factored into the material choice to ensure long-term durability.

By addressing these factors early in the design process, manufacturers can create systems that control vibration without compromising other performance requirements.

Testing Foam for Vibration Performance

Before foam materials are integrated into a production design, they undergo rigorous testing to ensure they meet performance requirements. Common evaluation methods include field simulation, which uses real-world equipment setups to validate lab tests and confirm performance standards. Additionally, Dynamic Mechanical Analysis (DMA) is used to measure the foam’s viscoelastic properties under vibration conditions. This measurement tells manufacturers the foam’s resistance to vibrations.

Testing provides quantifiable data that allows engineers to select the most appropriate foam for a given vibration control challenge.

Gaska’s Approach to Vibration Control Solutions

At Gaska Tape, we understand that vibration can be a serious threat to equipment reliability and structural integrity. Our engineered foam products are designed to provide both cushioning and stability in environments where vibration is unavoidable. By combining engineering expertise with flexible manufacturing capabilities, we help customers achieve durable, effective vibration control solutions that protect equipment and improve operational performance.

Vibration control starts with smart material selection and sound design practices. Whether you are developing a new product or improving an existing system, Gaska Tape can help you select and engineer foam materials that deliver proven vibration protection. Contact us to discuss your application, request samples, or collaborate on a custom solution built for your operating environment.