DESCRIPTION

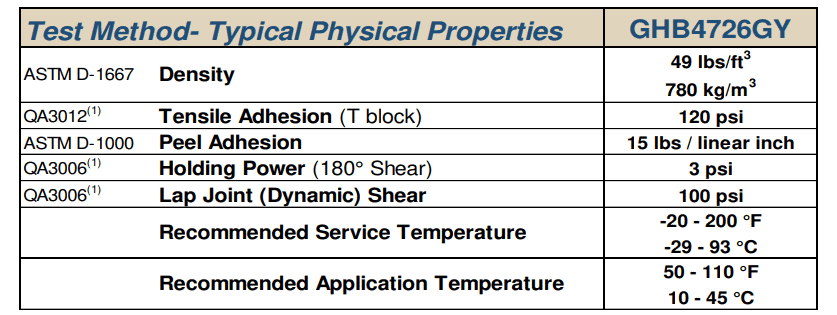

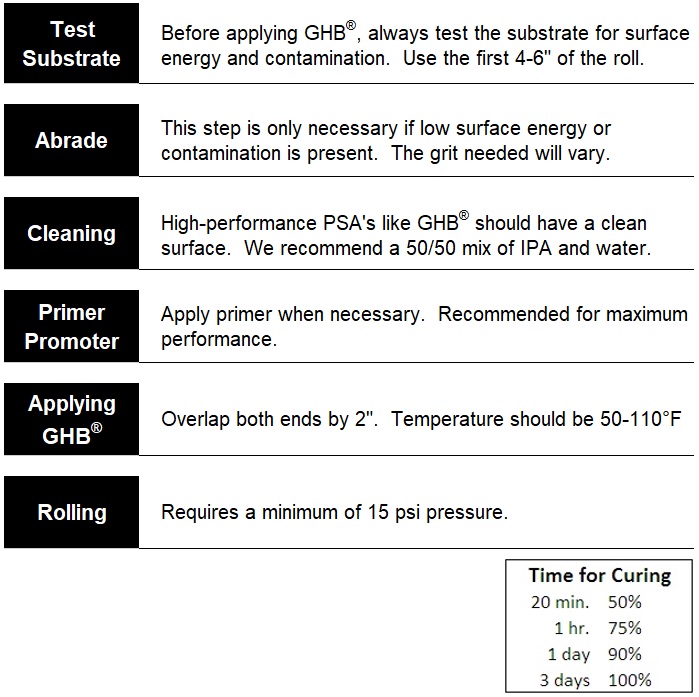

Gaska Hi Bond Adhesive (GHB®) is a high performance acrylic adhesive system. GHB4726GY is a gray foamed acrylic core that is coated on both sides with a high performance acrylic adhesive. This strong closed cell foamed core conforms to a wide variety of substrates, but is best suited for powder coated metals, steel, aluminum, ABS plastics, and some painted metals.

GHB® tapes are well suited for interior and exterior applications and in many instances can replace rivets, screws, welds and liquid adhesives. GHB® tapes will bond to most dry, clean, oil free surfaces. It provides bond strengths along with dynamic shear that is significantly higher than typical pressure sensitive tapes.