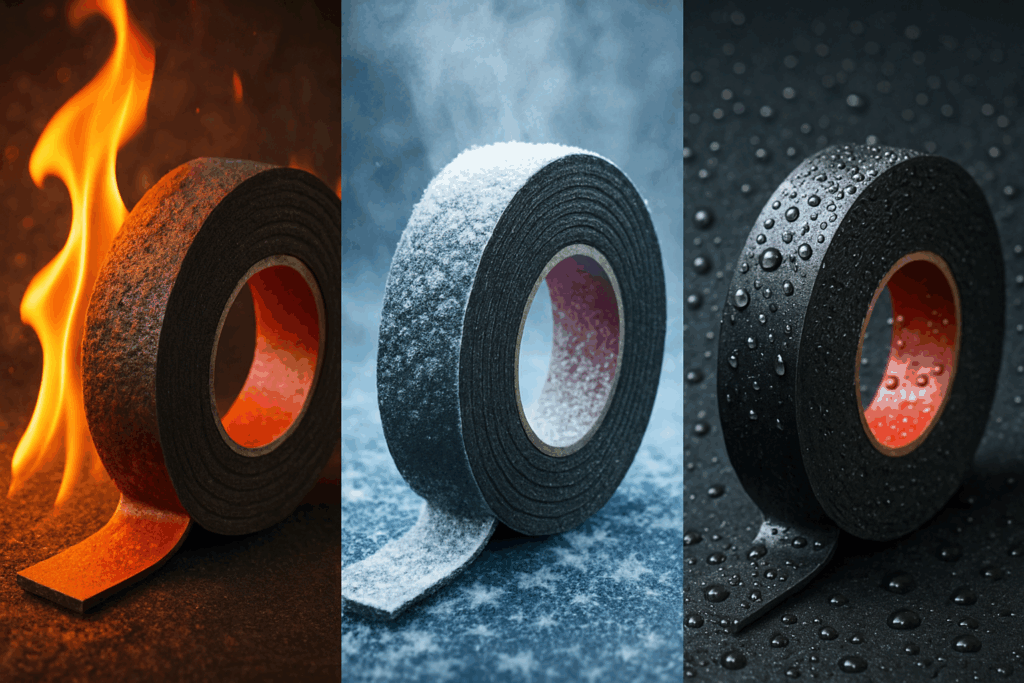

When your application demands performance in extreme environments, whether it’s intense heat, persistent moisture, or exposure to chemicals—selecting the right foam sealing tape is critical. In industries like automotive, marine, HVAC, construction, and heavy equipment manufacturing, a poorly chosen adhesive or substrate can result in equipment failure, compromised safety, or expensive maintenance.

In this guide, we’ll review the considerations for choosing the best gasket sealing tape and how Gaska’s engineered foam products are tailored for even the most extreme conditions.

The Importance of Environmental Sealing

Products that operate in outdoor or demanding industrial environments must be environmentally sealed to maintain functionality, safety, and longevity. Environmental sealing prevents the ingress of dust, water, air, UV rays, or chemicals that could corrode, contaminate, or compromise system performance.

Foam sealing tape provides a versatile sealing solution that can conform to uneven surfaces, absorb vibration, and maintain long-term integrity under compressive stress. Whether used in automotive door assemblies or marine control panels, these tapes offer crucial protection against environmental threats.

Key Properties for Harsh Conditions

Selecting the right foam tape begins with understanding the mechanical and environmental demands of your application. Below are essential properties to consider:

Closed-Cell vs. Open-Cell Foam Structure

- Closed-cell foam is ideal for outdoor and industrial environments because it resists water, air, and dust penetration. It also offers excellent insulation.

- Open-cell foam provides greater flexibility and sound absorption but is more porous, making it less suitable for sealing against fluids or gases.

Temperature Resistance

- Many industrial applications involve temperature cycling or high-heat environments. Look for foam tapes rated to withstand both low and high extremes. Gaska offers products that operate effectively from -40°F to over 200°F.

Chemical and UV Resistance

- UV rays and chemicals can degrade many foam materials over time. Choosing the right material—like EPDM, neoprene, or PVC, or Gaska Tapes Eco Seal Series—ensures long-lasting performance in harsh environments.

Compression Set and Recovery

- A good gasket sealing tape must recover its shape after compression to continue sealing effectively. Low compression set values ensure the tape maintains a strong seal even after prolonged pressure.

Adhesion Strength

- The adhesive backing must bond effectively with a variety of surfaces, including metal, plastic, and painted substrates. For some applications, a high-tack acrylic adhesive is preferable for long-term durability. Based on the substrate the foam adheres to, Gaska Tape offers several options to meet the requirements..

Flame Resistance (Optional)

- For applications, where flame resistance is important, Gaska Tape has options for those requiring a UL94 rating or meeting FMVSS302A.

Common Applications for Gaskets and Foam Sealing Tapes

Gaska’s high-performance tapes are used in a wide range of harsh-environment applications. Some examples include:

Automotive and Transportation

- Door seals

- HVAC system seals

- Dashboards and instrument panels

Marine Equipment

- Vibration-damping gaskets

- Engine enclosures

- Instrument gauge weather seals.

- Gaska High Bond Tape for applications requiring a permanent bond.

HVAC and Industrial Enclosures

- Sealing ductwork

- Air handling unit doors

- Electrical panel gasketing

- Filter frame sealing

- Moisture Barrier

Building and Construction

- Exterior window and door weather stripping

- Curtain wall spacer tape

- Insulated panel interfaces

- Expansion joint fillers

Choosing the Right Foam Material

Gaska offers several foam types to suit different applications. Here’s how some of the most common materials compare:

PVC Foam

- Excellent for vibration dampening

- High flexibility and conformability

- Available in UL-rated versions

- Ideal for HVAC, appliance, automotive, recreational, retail, transportation, medical and construction applications

- Great thermal barrier between dissimilar metals

- Closed-cell effective air, moisture, dust seal

EPDM Foam

- High resistance to UV, ozone, and weathering

- Excellent for outdoor use and automotive seals

- Maintains flexibility across a broad temperature range

Neoprene Foam

- Good chemical and oil resistance

- Flame-retardant options available

- Frequently used in marine and industrial gasketing

Polyurethane Foam

- Great for cushioning and sound absorption

- Typically open-cell, better suited for indoor use

Performance Testing and Standards

When selecting a foam sealing tape for critical applications, ensure the product meets or exceeds relevant performance standards, such as:

- UL 94 (Flame resistance)

- FMVSS 302 (Automotive flammability)

- ASTM D1056 (Flexible cellular materials classification)

Gaska’s products are tested to meet or surpass these industry benchmarks, ensuring long-term reliability.

Custom Foam Tape Solutions from Gaska

Sometimes, off-the-shelf solutions don’t meet the precise needs of your application. That’s why Gaska offers customized foam tape solutions including:

- Customized densities, thicknesses, widths, and lengths

- Die-cut industrial and recreational applications

- Lamination of customer supplied materials to our foam to meet required specifications

- Color matching

- Additional liner options

- Reeled or spooled longer length tape options to create more efficiency in production lines

- Customer supplied materials can be incorporated

Our team works closely with customers to develop sealing systems that align with specific regulatory, mechanical, and aesthetic requirements.

Working with Gaska: Engineering Expertise That Performs

With decades of experience in foam innovation, Gaska brings a unique blend of material science, application engineering, and customer collaboration to every project. When you work with us, you gain access to:

- Expert technical support

- Application-specific material recommendations

- Prototyping and rapid sample delivery

- Scalable production for small to large volume needs

We help you move from idea to implementation faster, without compromising performance or quality.

Whether you’re building outdoor enclosures, manufacturing vehicles, or designing industrial HVAC units, the right gasket sealing tape makes all the difference. Selecting a tape that provides consistent, long-term sealing in harsh environments isn’t just smart, it’s essential.

Gaska Tapes’ range of foam sealing tapes are engineered for high performance in tough conditions, helping you reduce risk, extend product life, and ensure a safe, sealed solution.

Need help selecting the right foam tape? Contact Gaska today to speak with our materials experts or request a sample tailored to your environmental application requirements.